The technique

The technique consists in stabilization soil mixing with binders (lime and/or cement), in order to modify the characteristics of machinability and mechanical resistance.

The effect of treatment is to improve the mechanical characteristics of bearing capacity of land by reducing its intrinsic plasticity.

Through chemical and mechanical action of the binder (lime and/or cement), the terrain becomes less sensitive to atmospheric agents such as Sun, rain and frost; also decreases the alterations that it may suffer when the temperature changes.

Depending on the amount of lime and/or cement added to the soil and the water content of this, you can pursue two goals:

- Reclaiming: to facilitate the workability of the ground treated by reducing the natural moisture, decreased plasticity, the rise of the instant lift “IPI” and the possibility of an adequate compaction.

- Stabilization: to improve the mechanical properties of soil layer with pozzolanic reactions start setting (with the use of lime) leading over time to a considerable increase in the mechanical resistance of the material.

Materials

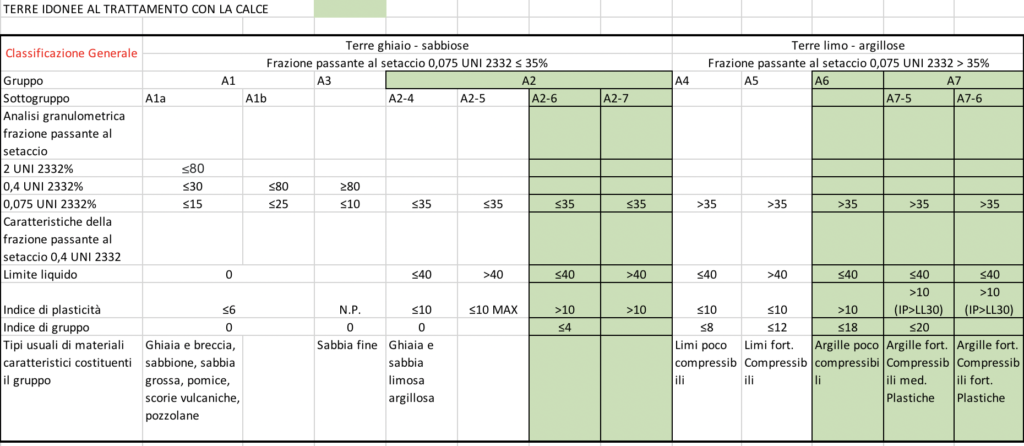

Lime is used to give the land, inconsistent or with poor load-bearing characteristics, improved mechanical properties by exploiting the interplay of wet clay particles with lime.

The development of hydrating lime reaction leads to a hardening of the mixture and then to an increase of load-bearing capacity of the soil treated. The scope of lime stabilization is very large, it acts to improve: country roads conditions, load-bearing capacities of laying plans road embankments, the reclamation of areas destined for urbanization and new buildings.

Technical advantages:

- Lift achieved significantly higher than the traditional 50-100%

- higher useful life of the package up to 100-200%

- high production (3000-5000 sqm/day)

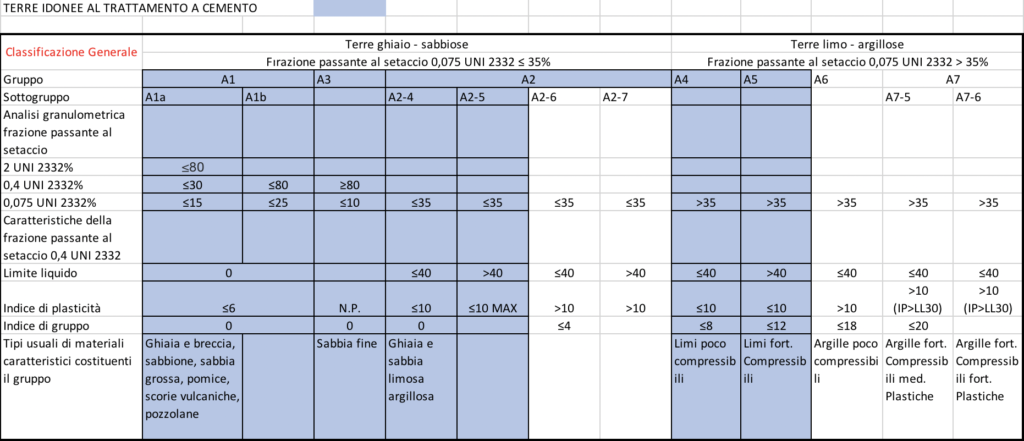

Cement is used to increase load-bearing capacities of road foundations with a stability compromised as a result of deep deformations of the road superstructure, or more generally to improve the classification of materials. Through this application you can create, in the site, a product even higher to mixtures that are prescribed for years in high streets with heavy traffic.

Technical advantages:

- Lift achieved significantly higher than the traditional, working on the most important thicknesses

- higher useful life of the package

- high production (4000-5000 sqm/day)

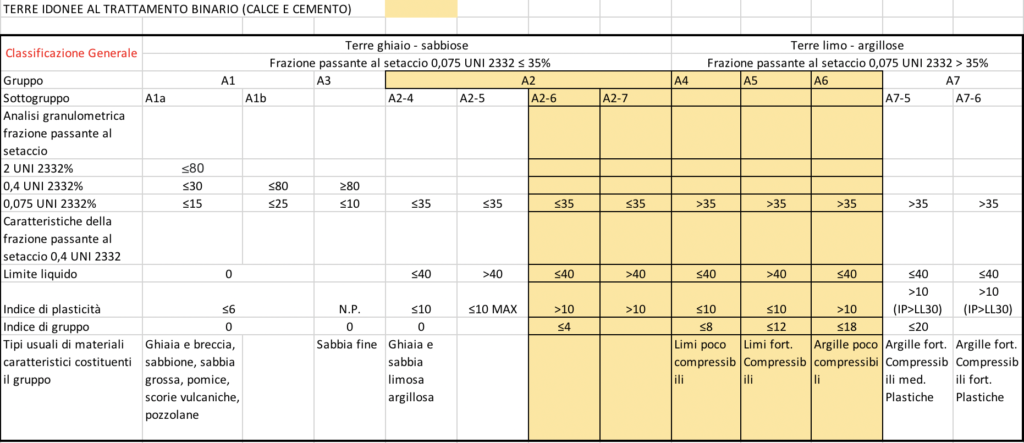

Binary treatment is carried out in special soils that are often not high plasticity indexes that will not only be treated with lime or cement. Since the particle size and the index model of soil treated are in a middle range, in order to ensure the proper carrying capacity and the required technical specification, the soil should be first stabilized waste by applying lime on the clayey fraction and then treated with cement on the sandy fraction, so as to create a Pozzolanic binder.

This treatment can be carried out also to get load capacity higher than those obtained with lime treatment alone or with only the concrete treatment.

Technical advantages:

- Lift achieved significantly higher than the traditional 50-100%

- package life 2-3 times above-average

Using all three soil stabilization techniques has the following economic and environmental protection advantages:

Economic advantages

- reduction or elimination of transporting materials to landfill

- reduction or elimination of purchase of Virgin material

- faster execution

Benefits of environmental protection

- reduction or elimination of supply material from quarries

- total Reuse of materials

- energy saving

- reduction of the traffic, pollution and wear and tear of the streets

Preliminary stage: the project of mixtures

Preliminary analysis of the land by defining its grain characteristic, size and all those necessary to study geological features a unique and precise mix design for soil to stabilize.

Preparation of the job site

Temporary construction works consist in the realization of the fundamental base camp, construction site and to the materials. For these accomplishments, the screeds can be made quickly and cheaply using the site to stabilize. Finally, a redeveloped and completed site may become a permanent artifact, such as a service road of the opera.

Soil preparation

Soil preparation includes the removal of the top layer, the aim is to eliminate the vegetation and the land rich of humus; You may also need to scarify the soil in order to dig in and prepare it to treatment and take out oversized rock elements.

The next stage is to determinate Earth’s natural moisture and, depending on the value found, it will be harrowed and ventilated to facilitate the evaporation of the water, when it is in strong excess value required for the mixture of the project.

It is important to mix very well with the material. The number of passes of pulvimixer depends by: the plasticity and moisture of the Earth, thickness and power of the machine used.

Compacting

Metal rollers at foot of mutton are convenient to consolidate screeds, clayey damp earth and lime made. Metal smooth rollers are particularly efficient with less plastic and granular lands; the rollers instead serve to trim layers of foundation or basis, to achieve high densities in the entire thickness.

Periodic checks

To measure the deviation from the optimal humidity, established for the mixture, you have to check soil moisture daily. Excess moisture otherwise requires increasing the dosage of binder material; in the opposite case you must humidify the blend ground-water calculated by adding material.

After repeated passages of pulvimixer it is important that the mixture is finely divided and homogeneous. Before compacting with rollers check the grain size, the homogeneity of the actual color, thickness of the mixture worked and his final moisture.

The goodness of compaction density occurred mainly with daily trials, and secondly with the test plate. Verification of flatness of finished detected ensures the quality of the superstructure.